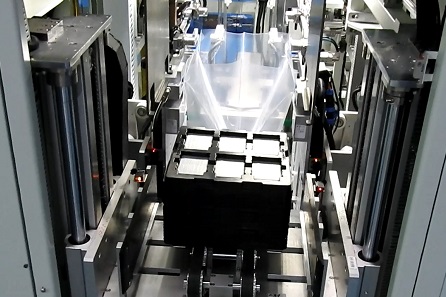

Fed by AGV, this intelligent packaging line can automatically fulfill a series of operations: scanning and weighing of the battery cell first, according to the scanned information, it select and prepare the right internal plastic bag and paper carton, then pack the cell into the bag, put the bag into carton, and label the carton with right battery information like model, weight and etc. that collected at the very beginning. According to the label information, a 6-axis robot located at the end of the line will unload the carton onto one corresponding pallet out of four. This packaging line is compatible with 4 kinds of cartons, accordingly, it supports independent palletizing on 4 pallets.

Key Features:

Compatible with 4 models of battery product

Support 4 types of carton

Supports independent palletizing

Modular function unit, easy to fit for different requirements and layout

Specifications:

| Pouch Battery Cell Packaging auto line | |

| Key Functions | Support up to 8 production lines' packaging task |

| Tray size | 282~430 224~350 130~280 (mm) |

| Carton size | 294~440 243~370 150~320 (mm) |

| Logistics line Height | AGV 380mm |

| Production capacity | PPM≥3 , stack weight within 30Kg |

| Line dimensions | 5400*16000*2700 (mm) |

| Modular function unit | bag-opening, carton-opening, AGV feeder, Barcode scanning, Weighting, staging, labeling |

Interior and Exterior:

*Note: Customized SPEC Accepted.

Get in touch with us here